Why Volkswagen tests its cars to the limit before they hit the road

Before any Volkswagen reaches South African showrooms, it undergoes extensive endurance testing in some of the world's most demanding local conditions.

Image: Supplied

Before a new Volkswagen reaches a South African showroom, it has already endured a harder life than most owners will ever put it through. Thousands of kilometres, tough road surfaces, extreme heat, altitude, dust and heavy loads are all deliberately heaped on.

Problems must be identified long before customers experience them, according to Siphesihle Notyena, senior endurance engineer at Volkswagen Group Africa (VWGA).

“Our responsibility is to ensure that the vehicle delivered to the customer is robust, reliable and fully compliant,” Notyena said at the recent VW Indaba in Kariega. “By the time it reaches production, it must meet our internal requirements, regulatory standards and customer expectations.”

What validation testing means

According to Notyena, validation and endurance testing are central to VWGA’s vehicle engineering operation. Every system, from drivetrain and suspension to electronics and safety systems, is evaluated before a car is approved for local production or sale.

“Our job is to make sure that when parts, systems and complete vehicles reach the production line, they’ve already passed through the correct processes and meet all requirements,” Notyena explained.

Vehicles are physically driven across South Africa in conditions that mirror and often exceed real customer use.

Years into months

Endurance testing is designed to compress a vehicle’s lifespan into a short, punishing timeframe. One test vehicle recently completed 100,000 kilometres in just 30 weeks, the equivalent of a full three-year warranty cycle.

“Through continuous driving, we accelerate the vehicle’s entire lifespan. The goal is to identify issues early, validate new components and technologies, and confirm that the vehicle remains safe, comfortable and reliable over time.”

Testing covers engine and transmission performance, suspension durability, braking behaviour, electronic systems, structural integrity and comfort-related factors such as noise, vibration and harshness.

The temperature chamber tests cars in extreme heat and cold.

Image: Brendon Staniforth

Why SA matters

South Africa plays a crucial role in Volkswagen’s global validation process. Local conditions are regarded as among the toughest anywhere in the world.

“Our roads, climate and altitude variations are extremely demanding,” Notyena said. “That’s why vehicles built anywhere in the world are validated here against South African conditions.”

Endurance routes are selected for complexity rather than distance. Vehicles are exposed to coastal humidity and salt air, high-altitude driving that stresses cooling and power delivery, gravel roads that test suspension and dust sealing, long highways for stability and fuel efficiency, and urban traffic that loads brakes, gearboxes and cooling systems.

“This ensures that any model entering our market isn’t just globally robust, but specifically prepared for African conditions,” he added.

More than driving

Every test vehicle is instrumented and monitored.

Before testing begins, vehicles undergo full inspections and calibration of driver-assistance systems. During testing, 270 kilograms of water-filled dummies are added to simulate passengers and luggage.

“We equip vehicles with data loggers that record electronic signals in real time,” Notyena explained. “If a driver experiences an issue, they create a digital marker so engineers can pinpoint exactly when and where it occurred.”

Dash cameras, voice recorders, precision gauges and diagnostic tools provide additional information, linking data to road conditions and driver feedback.

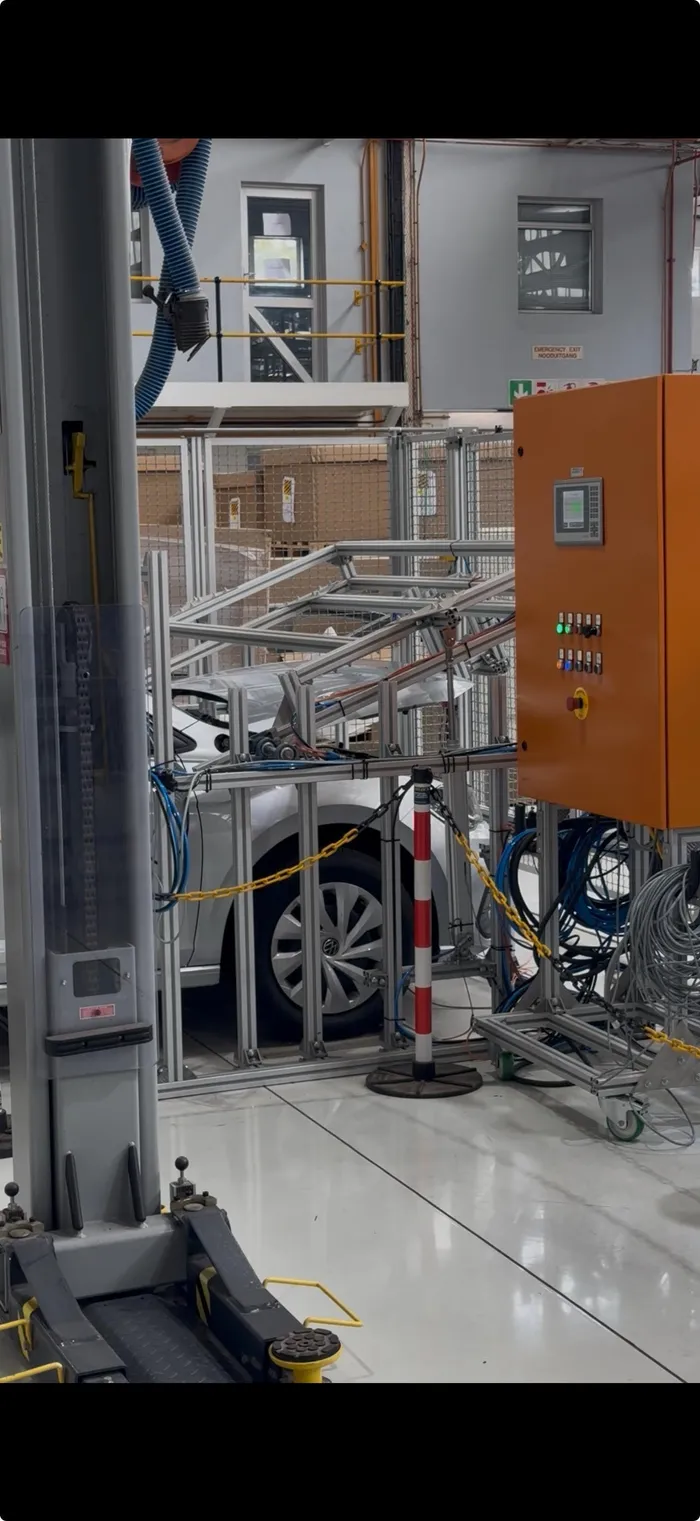

Validation and endurance testing are central to VWGA’s vehicle engineering operation.

Image: Brendon Staniforth

Problems are a good thing

“A problem isn’t a setback; it’s a win, every issue we identify protects the customer from experiencing it later.”

Issues are logged, analysed, traced to their root cause and resolved before being validated again. If a critical warning, such as an airbag fault, appears, testing stops immediately until the issue is fully understood and resolved.

Daily inspections track wear across interiors, exteriors, electronics and structural components that can reveal long-term issues before they become visible issues.

Real-world matters

While Volkswagen also uses advanced test rigs and simulation tools, they insist real-world endurance testing remains essential.

“Nothing beats putting a vehicle into real conditions,” Notyena said. “Test rigs confirm that components meet requirements, but the road shows us how the complete vehicle behaves as a system.”

By using both simulation and real-world endurance, VW ensures that nothing is left to chance.

Bottom line

In the past year, the endurance programme has covered approximately 2.47 million kilometres, the equivalent of driving around the world 60 times.

“At the end of the day, everything comes back to trust,” says Notyena. “Our goal is to deliver a product that customers can rely on for years, no matter where or how they drive,” Notyena concluded.

Related Topics: